Concrete has been an essential building material due to its versatility and durability for decades. It’s a mixture of cement, sand, aggregate, water and admixtures. Concrete is widely used in the variety of constructio including residential buildings, commercial building, industrial buildings and more. As per your requirement, you can use the different types of concrete such as reinforced concrete, plain cement concrete, polymer concrete, etc. according to their properties and usage.

Sounds interesting!

So, Brick & Bolt presents a detailed guide on the polymer concrete, it’s one of the most beneficial types of concrete. This guide will serve all the details including what polymer concrete is, the types of polymers used in it, types of polymer concrete, its applications, properties, advantages and disadvantages.

What is Polymer Concrete?

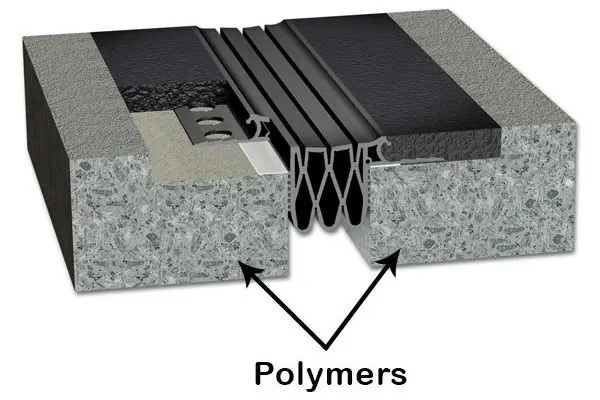

Concrete that uses polymer as a binder instead of cement is known as polymer concrete. Sometimes, the polymer is combined with Portland cement to create Polymer-Modified Concrete (PMC), Polymer Cement Concrete (PCC) and Polymer Impregnated Concrete (PIC).

Depending on the composition, polymer concrete composites have unique characteristics, including high tensile, flexural, and compressive strengths; long-lasting durability regarding freezing and thawing action; good adhesion to most surfaces; good chemical resistance; low permeability to water; and lightweight. They also cure quickly at ambient temperatures between –18 and +40°C (0 and 104°F).

Types of Polymer Materials Used in Polymer-Modified Concrete

The following resins are used to make polymer-modified concrete:

- Unsaturated Polyester Resin

- Epoxy Resins

- Methanol

- Vinyl Acetate-Ethylene (VAE)

- Furan Resins

- Styrene-Butadiene Resin (SBR)

- Styrene and Polyester Styrene

- Methyl Methacrylate MMA

- Polyvinyl Acetate (PVA)

- Acrylics and Styrene-Acrylics

- Poly Urethane Resins (PUR), etc.

Types of Polymer Concrete

- Polymer Concrete (PC)

- Polymer Impregnated Concrete(PIC)

- Polymer Cement Concrete(PCC)

Let’s dive deeper into all types-

1. Polymer Concrete (PC)

In polymer concrete, aggregates are bound with a polymer binder instead of cement, as in traditional concrete. In order to reduce the amount of polymer required to bind the aggregates, the primary method in Polymer Concrete is to decrease the void volume in the aggregate mass. To achieve the highest density and lowest void volume, the aggregates must be appropriately graded and mixed. To make the polymer concrete, you need to take graded aggregates in a mould, and then the monomer is spread through the aggregates to start the polymerization by using radiation or a chemical process. In addition, a silane coupling agent is mixed with the monomer to enhance the bond strength between the aggregates and the polymer.

2. Polymer Impregnated Concrete (PIC)

The most common type of polymer composite is polymer-impregnated concrete. The concrete is precast and conventional, and it is dried and cured in an oven or by dielectric heating. The air in the open cell is then drawn out using a vacuum. Afterwards, a monomer with low viscosity is spread throughout the exposed cell and polymerised through the application of heat, radiation, or chemical initiator.

3. Polymer Cement Concrete (PCC)

Cement, aggregates, water, and monomers are combined to create polymer cement concrete. After that, the mixture is cured, dried, and polymerized in moulds. Polyester-styrene, epoxy-styrene, furans, vinylidene chloride, and other monomers are utilized in PCC.

Uses of Polymer Concrete

Polymer concrete is utilised in specialised construction projects where resistance to multiple forms of corrosion and long-term durability are required. It can be applied in the same way as regular concrete. Polymer concrete is most suitable for the construction works like-

- Repair to corrosion-damaged concrete,

- Marine works,

- Prestressed concrete,

- Electrical or industrial construction,

- Road construction,

- Nuclear power plant construction,

- Irrigation works,

- Waterproofing of structures,

- Sewage works and desalination plants,

- Prefabricated structural components like manholes, acid tanks, drains, highway median barriers, etc.

Properties of Polymer Concrete

1. Strength

Compared to cement concrete, it has superior tensile, flexural, and compressive strengths, as well as good abrasion resistance.

2. Durability

Minimizing the infiltration of salts and chlorides provides good long-term durability to concrete against chemical attack and freezing and thawing cycles.

3. Rapid Curing

The effect of curing is quick at room temperature (–18 to +40°C). While conventional concrete only gains 20% of its 28-day strength in a single day of curing at room temperature, polymer concrete develops 70% of its strength after just one day.

4. Good Adhesion

Polymer concrete has good adhesion to the old surface, enhancing the bond strength of most surfaces.

5. Low Permeability and Lightweight

It has a low water permeability and makes lightweight concrete.

Advantages of Polymer Concrete

The following are the advantages of polymer concrete:

- Polymer concrete offers excellent resistance to both corrosion and chemical reactivity.

- Applying polymer concrete in extremely thin cross-sections is possible.

- Polymer binders are helpful for repairing old structures because they set quickly and provide resistance to the weathering effect.

- It decreases the shrinkage.

- It decreases carbon dioxide intrusion, protecting concrete from carbonation and resulting in a decrease in alkalinity.

Disadvantages of Polymer Concrete

The following are the advantages of polymer concrete:

- Skilled labour is required to mix the polymer concrete.

- Compared to conventional concrete, polymer concrete is much more costly.

- It is crucial to wear masks and hand gloves to protect your skin from the potentially hazardous chemicals and resins used in polymer concrete.

- It is necessary to design the mix properly because it is possible for two-component materials to be improperly proportioned.

Conclusion

On a final note, polymer concrete offers a remarkable range of benefits and uses since the polymer is used as a binder rather than traditional cement. It is useful for a variety of construction projects, including corrosion repair, marine construction, and electrical infrastructure, due to its exceptional strength, durability, and resistance to corrosion. Polymer concrete is a valuable building material in modern construction because of its adhesion properties, quick curing time, and reduced permeability. These properties make it more expensive and labour-intensive, but it also provides innovative solutions for improving structural integrity and longevity.