Steel and concrete are two of the most commonly used materials in the modern construction industry. Modern steel construction offers several benefits that make it superior to other conventional building materials like bricks and stones. Of the many types of steel, structural steel is especially beneficial. Continue reading to understand exactly what structural steel is, its properties, types, grades and standards in India.

What is Structural Steel?

Structural steel is a metal alloy of iron with Carbon, Manganese and other such elements which give it high strength. It is used to build load-bearing elements—such as beams, columns, foundations and roofs—in steel structure construction. Structural steel detailing in buildings can be done using various shapes, forms, sizes and grades of the material, enabling versatility in architectural design. Modern steel construction can also be executed much faster than conventional building techniques, making it popular globally, especially for large-scale commercial structures.

How is Structural Steel Made?

The structural steel fabrication and manufacturing process follows the below steps:

- Raw Material Preparation: Iron ore is extracted and loaded onto a blast furnace. Here, small quantities of scrap steel, carbon and limestone are added.

- Smelting: The mixture is heated up by the addition of oxygen. It is then subjected to extremely high temperatures, creating molten iron, which is then refined to remove impurities and produce pure steel.

- Moulding: The steel undergoes processes like water jet cutting, laser cutting and plasma cutting to produce the desired shapes. Individual steel components are then welded, bolted or riveted together to produce the final structural steel shapes.

Structural Steel Grades

According to the Indian Standards IS 2062 (2011) Code: Hot Rolled Medium and High Tensile Structural Steel, there are nine structural steel grades with the following compositions:

| Grade | Carbon (C) | Mn (Manganese) | S (Sulphur) | P (Phosphorous) | Si (Silicon) |

| E 250 | 0.2 – 0.3 | 1.5 | 0.040 – 0.045 | 0.040 – 0.045 | 0.4 |

| E 275 | 0.2 – 0.3 | 1.5 | 0.040 – 0.045 | 0.040 – 0.045 | 0.4 |

| E 300 | 0.2 | 1.5 | 0.040 – 0.045 | 0.040 – 0.045 | 0.45 |

| E 350 | 0.2 | 1.55 | 0.040 – 0.045 | 0.040 – 0.045 | 0.45 |

| E 410 | 0.2 | 1.6 | 0.040 – 0.045 | 0.040 – 0.045 | 0.45 |

| E 450 | 0.22 | 1.65 | 0.040 – 0.045 | 0.040 – 0.045 | 0.45 |

| E 550 | 0.22 | 1.65 | 0.02 | 0.025 | 0.5 |

| E 600 | 0.22 | 1.7 | 0.02 | 0.025 | 0.5 |

| E 650 | 0.22 | 1.7 | 0.015 | 0.025 | 0.5 |

From E 250 to E 650, each of these grades have increasing strength. Some of the other common standards used in India are:

- ASTM (American Society for Testing and Materials) standards, which qualify the metal into grades ASTM A36, A500, A572, A588, A709, A992, A285, A514 and A516.

- European (EN) standards, which qualify structural steel grades as EN 1.0038, EN 1.0145, EN 1.0045, EN 1.0117, EN 1.0044, EN 1.0553, EN 1.8827 and EN 1.0577.

Material Properties of Structural Steel

- Tensile Strength: Structural steel is known for its exceptional tensile strength, which refers to its ability to resist tension or pulling forces without breaking. Depending on the grade, the ultimate tensile strength of commonly used structural steel typically ranges between 410 to 550 MPa. This makes steel an ideal material for steel bridges, steel girders and steel trusses.

- Ductility: Ductility is a material’s ability to deform without breaking, collapsing or undergoing structural failure. It is represented by the modulus of elasticity, whose value is around 200 GPa for structural steel. High ductility allows steel frames and sections to be easily moulded into a diverse range of shapes and forms.

- Weldability: Structural steel is easily weldable. It can be easily cut, assembled, installed, and fabricated on construction sites, enabling quick structural steel connections between different components.

- Durability: This steel has high resistance to wind loads, earthquakes and degradation, enabling it to survive for hundreds of years.

- Fire Resistance: The material is not combustible and does not aid in the spread of fires. However, the material starts losing its strength at temperatures higher than 500°C.

- Corrosion resistance: Typically, the material is not corrosion resistant and gets easily rusted when exposed to prolonged moisture or humidity. However, corrosion-resistant coatings, such as paint or chemical coats, can be applied to prevent this.

According to the Indian Standards Code IS 2062 (2011), the following are the properties of different steel grades:

| GradeTensile Strength (MPa) | Tensile Strength, Min (MPa) | Yield Stress ReH, Min(MPa) | Percentage Elongation A, Min at Gauge Length, Lo=5.65 | Internal Bend Diameter Min | |||

| <20 | 20 – 40 | >40 | <20 | >20 | |||

| E 250 | 410 | 250 | 240 | 230 | 23 | 2t | 3t |

| E 275 | 430 | 275 | 265 | 255 | 22 | 2t | 3t |

| E 300 | 440 | 300 | 290 | 280 | 22 | 2t | – |

| E 350 | 490 | 350 | 330 | 320 | 22 | 2t | – |

| E 410 | 540 | 410 | 390 | 380 | 20 | 2t | – |

| E 450 | 570 | 450 | 430 | 420 | 20 | 2.5t | – |

| E 550 | 650 | 550 | 530 | 520 | 12 | 3t | – |

| E 600 | 730 | 600 | 580 | 570 | 12 | 3.5t | – |

| E 650 | 780 | 650 | 630 | 620 | 12 | 4t | – |

Types of Structural Steel

According to the ASTM (American Society for Testing and Materials) standards, there are five main types of structural steel:

| Steel Type | Composition | ASTM Number | Available Shapes and Forms |

| Carbon Steel | Has a Carbon content between 0.2 – 2%, Copper <0.4%, Manganese 1.6% and Silicon 0.6% | A36 | Plates, bars, sheets, strips, rivets, bolts and nuts |

| A529 | Plates, structural shapes and bars | ||

| High Strength Low Alloy (HSLA) Steel | Manganese 2%, along with small portions of alloys like nickel, molybdenum, nitrogen, vanadium, niobium, and titanium | A441 | Plates, structural shapes, pipes and bars |

| A572 | Plates, structural shapes and bars | ||

| Corrosion Resistant HSLA Steel | Apart from the HSLA steel components, this contains additional chromium, copper, molybdenum and nickel | A242 | Plates, structural shapes and bars |

| A588 | Plates, structural shapes and bars | ||

| Quenched and Tempered Alloy | Similar composition as HSLA steel, but its manufacture involves reheating and rapid cooling to enhance strength. | A514 | Plates, structural shapes and bars |

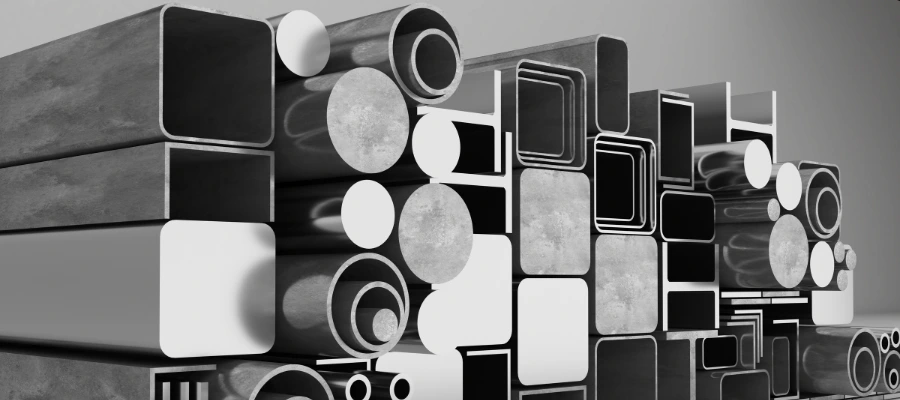

Common Structural Steel Section Types

According to the Indian Standards Code IS 808:1989 and IS 4923:1997, structural steel is available in different shapes and sizes, including:

Structural Steel Beams or I Section Beams

These are also called rolled steel joists and consist of one web and two flanges, forming an I-shape. They are classified into four types:

- Indian Standard Junior Beams (ISJB)

- Indian Standard Lightweight Beams (ISLB)

- Indian Standard Medium weight Beams (ISMB)

- Indian Standard Wide flange Beams (ISWB)

Steel Columns/ Heavy Weight Beams

These are steel beams or columns that have a much higher compressive and tensile strength and are classified as:

- Indian Standard Column Sections (ISSC)

- Indian Standard Heavy weight Beam (ISHB)

Angles

Angles have two legs which are connected to each other at a 90 degree angle and can be classified as:

- Indian Standard Equal Legs Angles (ISA)

- Indian Standard Unequal Legs Angles (ISA)

Channels

Channels are C-shaped structural steel sections and are classified as:

- Indian Standard Junior Channels (ISJC)

- Indian Standard Lightweight Channels (ISLC)

- Indian Standard Medium weight Channels (ISMC)

- Indian Standard Medium weight Parallel flange Channels (ISMCP)

Hollow Sections

Structural steel hollow sections are of three types:

- Circular Hollow Sections (CHS)

- Square Hollow Sections (SHS)

- Rectangular Hollow Sections (RHS)

Apart from these common types, steel construction also involves structural steel bars, plates, sheets and H beams.

Using the Best Structural Metal in Your Project

Steel frame structures are increasingly gaining popularity in India, especially for commercial construction. However, it can be difficult to source the right grades and qualities of steel, as well as find skilled structural steel fabricators. Brick & Bolt, an end-to-end construction services provider, employs the best contractors and provides top quality building materials supply in all its projects. Skilled design by experienced architects, as well as premium quality assured by 470+ quality checks, have made the company a leader in the industry. To ensure that your structural steel building uses the best materials and is beautiful as well as functional, reach out to Brick & Bolt today!